Traditional Only® Taper Tool Review

Featured Deal

From $7.50

Get DealTraditional Only® Taper Tool

Made in the USA! Made for Traditional Archers! The Traditional Only® Taper Tool is a miracle in your pocket! ...read more

$7.50

$5.25

$6.75

Traditional Only® Taper Tool For Sale

Most Popular Arrow Tools & Accessories

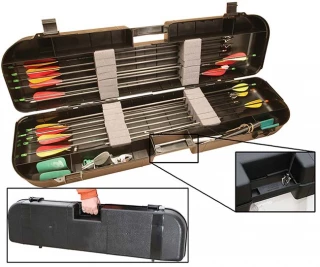

MTM Arrow-Plus Case

Rugged arrow cases from MTM are a traveling archer's favorite. Made of... read more

Ace Spine-Master Spine Tester

Finally! A spine tester for the home wood arrow builder that won't... read more

Great Northern Feather Processing Jig

With the built-in guide controls, you can produce precision grinds to both... read more

Replacement Indexer for Bitzenburger Dial-O-Fletch Fletching Jig

Replacement (or extra) fletching indexer for the Bitzenburger Dial-O-Fletch fletching jig. Looking... read more

Bitzenburger Bearing Spring

Replacement (or extra) bearing spring for the Bitzenburger Dial-O-Fletch fletching jig. Sold... read more

Traditional Only® Taper Tool Reviews

East to work

Work great

I like that there is a quality yet inexpensive version of th

Twist an go

Love it

works great... just hard to guess which end is which... new builder here.

I would buy this product again

tapered arrow shafts well

I would not purchase this product

It will taper correctly. The plastic housing is no good too weak. Needs to be made of metal.

Absolute trash !!!

this tool worked for one arrow. The next three it tore them up so bad I could not put a knock or a broadhead on the shaft.

Easy use

Quick sharpening, very accurate

Perfect Cuts — Nice Tool

This taper tool cuts very uniform and smooth tapers in Port Orford cedar arrow shafts. The tool is very well made and seems quite sturdy so far. I have only trimmed about 40 arrows front and back so the taper tool has not been used extensively. However, I have noticed NO indication that the blades are getting dull after about 80 total trims. I truly like this tool because it… read more is so precise and easy to use. Only extensive use will tell if it will remain sharp over the long haul.

Great product

Lot easier than disc sander jig I was using.

It does the job.

An inexpensive way to taper woodies for nocks and points. It does the job just fine.

Traditional Only® Taper Tool Questions and Answers

Does the angle of the taper on a wood arrow have to be the same as that of the steel broadhead being installed on it? I have 5/16 arrows and no taper tool that I have tried fits the opening/base on the bear broadheads that I like, so I'm "guessing" when I

With wood arrows they do require using the same degree of taper. This allows them to go on straight.

I am new to archery and I bought this taper tool to make my own arrows. This question might have been answered before but I can't find the answer. Which side of this tool is used to taper the nock end and which side is used to taper the front end of the

The long blade does the point taper, and the short blade does the nock taper.

Nick -- The longer, more gradual taper fits points; the shorter, steeper taper fits nocks. Referring to the picture, the side for tapering points is marked "11", while the side for nocks is marked "MADE IN USA". If you really want to feel comfortable with this, cut some tapers on a piece of hardware-store dowel, and test-fit your nocks and points. -- Chuck Decatur, GA

The side with the longer taper (longer blade) is for points and the shorter side is for nocks.

I actually use both for the arrow tip--the short taper tool part to start and the narrow to finish. I've never set my own nocks, though, so it might work well for that too (I'd start with the short end). Good luck!

Is this tool suitable for bamboo arrows?

I would not recommend this tool for anything harder than cedar or pine.

This tool works like a charm on cedar . . .like sharpening a pencil only it stops before it makes a point. I've made arrows out of bamboo and common reed (phragmites communis). I would recommend filling the open end of the bamboo with wood (a shaved down dowel, stick, bamboo skewer, a stick). It's pretty easy to do. Glue it in and cut it to length. The taper tool should work then. Be aware that the tool is meant to cut aspen/cedar that is soft. I'm sure it will cut bamboo but it will dull eventually.

Does the angle of the taper on a wood arrow have to be the same as that of the steel broadhead being installed on it? I have 5/16 arrows and no taper tool that I have tried fits the opening/base on the bear broadheads that I like, so I'm "guessing" when I

With wood arrows they do require using the same degree of taper. This allows them to go on straight.

Can I use this tool on fiberglass dowels? I want to make fiberglass arrows and I have no idea if I can use this tool or not.

I have not tried it on fiberglass, but I don't believe it would work very well and would not recommend it.

It put a beautiful nock taper on the fiberglass shafts that I'm building for bowfishing. Couldn't have worked any better! I have a long draw, and the white fiberglass arrows that are available are just too short. I purchased some orange driveway markers from a home improvement store, and the 5/16" taper tool worked great on these.

Fiberglass arrow shafts, no - I wouldn't try it. But fiberglass stakes, like you use to line a driveway? Absolutely - I've used it for just that thing, when I turned one into a heavy shaft (1200 grains, 28" long). Worked very nicely, and produced less fiberglass dust (ick!) than grinding would have.

This sharpener is designed for wooden shafts. If you are going to taper fiberglass shafts, it would be far better to use a belt sander or disc sander using fine or medium sandpaper.Of course you should use a dust mask and eye protection while doing the proceedure to protect you lungs and eyes from any particles created during the process. This also assumes that the shafts are solid and not hollow. Regards dj

Honestly I'm not sure. I think it's only used for wood arrows, it acts kind of like a pencil sharpener, shaving away excess wood into the shape and size for an arrow head. Sorry if that doesn't help. Good luck.

i've only used this on wood! not to sure if you should try it on fiberglass,doesn't seem strong enough? Just my opinion. Sent from my iPad

You can try, but you may break the tool. This tool is not very durable. I would look for one made of metal if I were you.

The short answer is: I don't know. I think it might work but probably wouldn't last very long because fiberglass is fairly abrasive. Good luck! -- Chuck Cochran

I have never used it on a fiberglass shaft.. only wood. I would suspect that the fiberglass, being harder, would dull the blade edge pretty quickly, even if it did work. It might also cause the fiberglass shaft to splinter.. You might try a standard pencil sharpener on a piece of scrap fiberglass shaft to see if it works.. if it does, the product should also, but, again, it will probably go dull quite quickly. If you do try it, please let me know how it went.. others may have the same question. Al

Which opening is the side for tapering points,

the longer blade does the point end(longer taper)

The shaver has a short taper and one that runs almost the length of the device. The longer taper is for the points and the short is for the nocks. Hint: be sure you have the correct shaver for your arrow shaft diameter. The same goes for the points and nocks. Good luck! Al Sent from my iPhone

Can I use this on chundoo arrows, and how many arrows can I taper before the blades are no longer useful?

Not sure about the chundoo arrows if they are wood then yes you can. The taper tool last for several dozen shafts.

I am new to archery and I bought this taper tool to make my own arrows. This question might have been answered before but I can't find the answer. Which side of this tool is used to taper the nock end and which side is used to taper the front end of the

The long blade does the point taper, and the short blade does the nock taper.

Nick -- The longer, more gradual taper fits points; the shorter, steeper taper fits nocks. Referring to the picture, the side for tapering points is marked "11", while the side for nocks is marked "MADE IN USA". If you really want to feel comfortable with this, cut some tapers on a piece of hardware-store dowel, and test-fit your nocks and points. -- Chuck Decatur, GA

The side with the longer taper (longer blade) is for points and the shorter side is for nocks.

I actually use both for the arrow tip--the short taper tool part to start and the narrow to finish. I've never set my own nocks, though, so it might work well for that too (I'd start with the short end). Good luck!

If I buy 11/32 shafts that are tapered to 5/16 will I have to get two different sized taper tools?

If you were to purchase the tapered cedar arrows the 5/16 nock end will already be tapered. So you will need just the 11/32'' taper tool.

You will need a separate tool for 5/16. This will only taper 11/32 shafts..... Sent from my iPad

The Traditional Only plastic taper tool works only on one size shaft; so yes, I think you will need two. Another option is the Tru-Center tool: http://www.3riversarchery.com/product.asp?i=5346. -- Chuck Cochran Decatur, GA

Maybe this will help;When you purchase your wood shafts have the company taper the knock end prior to shipment.Then purchase your taper tool at 11/32 so you can cut your arrows at the proper draw length and then taper them, usually one inch past your hand.An 11/32 nock will work on a 5/16 taper.It will slightly extend over the taper but I have used this many times and it has never came off or effected the arrows flight.Hope this will help,Rick Sr.

Are replaceable blades available for this taper tool?

The blades are not replaceable

No, they are just like pencil sharpeners, non replaceable blades.

No the blades are not replaceable

How long does the 23/64 tap the shaft?

The 23/64 will taper a 3/4" taper on the point end.

My arrows are 9mm wide what size tool will I need

We don't carry a taper tool for that size. You will have to use a wood chuck tapering tool we have them online.